Reducing HCAIs in healthcare settings

Sluice rooms and bedpan washer disinfectors are critical in the fight against Healthcare-Associated Infections (HCAIs). These designated spaces...

Our bedpan washer disinfectors (sluice machines) are designed for maximum efficiency and ease of use, providing a seamless and reliable decontamination every time.

The machines work by disposing of the contents of the bedpans and urine bottles, thoroughly cleaning and removing soil, followed by thermally disinfecting with steam to remove pathogens and microorganisms, stopping the spread of infections and ensuring safe reuse.

Prepping the machine for use

Correct loading of the machines is crucial in ensuring utensils are cleaned thoroughly; for example, bedpans should be placed facing the spinners/jets and not overloading the machine with utensils.

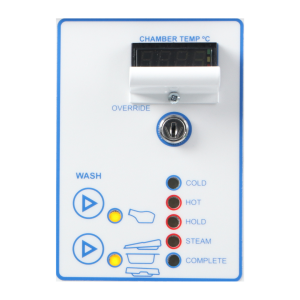

That’s why we provide easy to follow loading charts and operation manuals with each bedpan washer disinfector we install. Our machines also have clear digital displays and instructions; these clear instructions and charts ensure optimal cleaning and decontamination with every cycle, simplifying operation for staff and providing consistent results.

It’s important to note that you should only put human waste and toilet paper into the machine. Other items, such as gloves, wipes, and sanitary products, can cause blockages. A full list of what not to include can be found in our operation manuals.

To aid in infection prevention, all of our bedpan washer disinfectors can be opened hands-free, either with a foot pedal or sensor.

The Wash Cycle

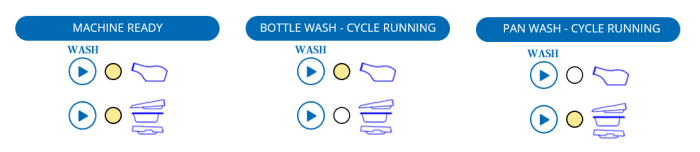

Once you have loaded the machine, you can select one of the two wash cycles the machine offers, which include a bottle wash (normal) and a bedpan (super) wash.

A bottle (normal) wash includes:

A bedpan (super) wash: provides a PRE WASH stage, which includes a 30-second continuous burst of water at the beginning and then follows the above steps of a normal wash.

During the machine’s cool-down phase, the descaling pump is activated to reduce limescale buildup. This is important as limescale is one of the biggest causes of preventable breakdowns. If you need a descalent pump connected to your bedpan washer disinfector or you need a fluid refill, our sales team are happy to help via sales@stanbridge.co.uk or by calling 01689 806 500.

After the wash cycle

When a wash cycle has finished, the bedpans can be placed on a rack to dry, ready to be reused. It’s important to ensure these are taken out with clean hands/gloves and are placed on the clean side of the sluice room to ensure there is no cross-contamination.

Our bedpan washer disinfectors are a quicker and more effective way to clean bedpans in a fast-paced environment, with each cycle lasting between 6 minutes and 30 seconds and 8 minutes. This helps to free up staff’s valuable time, allowing them to spend more time with patients. It’s also a much safer option for staff as they will no longer need to wash the utensils by hand, where there is a higher risk of contamination, as manual cleaning does not offer the same level of protection.

Maintenance Checks

To keep your bedpan washer running effectively, it’s important to have regular services and perform regular maintenance, as this helps to extend the machine’s lifespan. This includes checking the temperature, deoscale levels, etc. If you ever experience an issue with your machine, we also have engineers on hand across the UK to help get your machine working again and minimise any downtime.

All of our washer disinfectors are manufactured to meet British Standards, the recommendations of WRAS, and meet EN ISO 15883-1 & ISO 15883-3.

You can find out more information about our Stanbridge bedpan washers by viewing our range here. Alternatively, you can speak to our experts on 01689 806500 for advice on the right sluice room equipment for your facility.

If you would like to speak with a member of the team at Stanbridge, please feel free to contact us using the details below, or alternatively complete the contact form on this page and we will get back to you shortly.

Stanbridge Ltd

Unit 78, Powder Mill Lane

Questor

Dartford

Kent

DA1 1JA

Tel: 01689 806500